CPI

Proven Solutions for the Global Compression Industry. Throughout the world, our customers count on us for service and solutions that keep their compressors, lubrication systems, and business running.

Get a Quote Now!

Proven Solutions for the Global Compression Industry. Throughout the world, our customers count on us for service and solutions that keep their compressors, lubrication systems, and business running.

Get a Quote Now!

With roots dating back to 1897, originally known as France Compressor Products, Compressor Products International (CPI) has grown tremendously, developing and acquiring new technologies and services to better meet the global needs of today’s reciprocating compressor operators.

Throughout the world, our customers count on us for service and solutions that keep their compressors, lubrication systems, and business running. With our thorough knowledge of compressor operation and extensive field experience gained from years of collaboration with compressor manufacturers and users, we are proud to help drive growth in the markets we serve.

Our health and safety goal is clear — to have the world's safest employees. All employees sign a pledge to help achieve this objective. We believe every accident can be prevented, and our safety framework is designed to eliminate all incidents associated with CPI activities, products and services.

Training and education programs and ongoing process improvement help ensure full engagement of our workforce in our safety goals. Safety must be present in every aspect of our product life cycle: from the suppliers with whom we partner, to the employees who build and distribute our products.

CPI is committed to keeping your compressors operating safely, reliably and profitably. View our informational videos to learn more.

Reciprocating compressors and particularly the main pressure packing cases are known to be large contributors to the overall gas emissions from plants. For this reason, CPI have invested much time and resources to develop unique solutions to help solve this industry wide problem.

CPI’s EMISSIONGUARD™ TR² packing ring is the only ring design that multiplies the benefits of a tangent to rod ring and a step tangent ring by combining the two rings into one, providing a more efficient seal whilst reducing the frictional load onto the piston rod.

Proven in the field to consistently reduce packing case vent leakage by 50% and more.

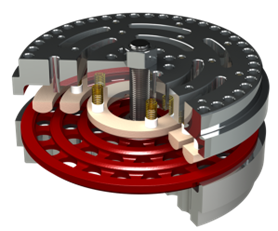

The CPI EMISSIONGUARD™ ES³ expandable static seal is the first seal designed for optimum sealing when your compressor is not running and remains pressurized.

CPI can supply a full control system which can interlock with the compressor controls to activate and deactivate the ES³ static seal only when the compressor is stopped.

Control and monitor the pressure of the buffer gas into the packing case assemblies.

Monitoring vent line pressure and flow enabling automatic regulation of the inert buffer gas pressure.

CPI’s purge panels ensure a positive buffer gas pressure in line with API618 to prevent process gas leakage into the distance piece.

Together with our EMISSIONGUARD™ family of products we also design, manufacture and supply all conventional main, intermediate and wiper packing cases and rings. CPI manufactures all of our polymer materials in-house using proprietary blends and methods. This ensures that we have total control of the quality and performance of our products. Our engineers select the best materials for each application to optimize the performance and reliability of our products in service.

CPI have built a reputation as a valve problem solver with our signature Hi-Flo™ Profiled Ring Valve range. Each valve is specifically designed for the application to provide reliability and durability.

We have also taken our profiled ring valve a step further by developing our Hi-Flo™ RS (Replaceable Seat) valve, this is based on our radius ring valve, bringing the same performance, but with the added advantage of not requiring any machining of valve seat, with a simple clean and replacement of all internal consumables including the non-metallic replaceable seat plate.

To access CPI's comprehensive collection of brochures for all valve products, visit the Technical Library below, select the brochures section and scroll down alphabetically to all literature prefixed Valves.

The oil and lubrication system plays a very significant role in the performance of a reciprocating compressor. Too much, too little or inconsistent delivery can reduce performance, lead to premature wear and potentially result in catastrophic failure.

CPI provides industry leading lubrication systems, products and services, partnering with our customers to develop individual solutions to their unique lubrication needs.

From individual components to complete, turnkey systems like our SAFEGUARD™ 1000 or SAFEGUARD™ 5000 lube consoles, we can provide the resources and expertise to ensure your compressor operates at peak performance and longevity.

To access CPI's comprehensive collection of brochures for all lubrication products, visit the Technical Library below, select the brochures section and scroll down alphabetically to all literature prefixed Lubrication.

CPI provides exceptional reconditioning services for restoring parts to their original specifications and performance.

Whenever a part has the potential to be made “good as new,” CPI has the expertise to make it happen. Using various NDT methods, CPI experts will carefully evaluate the condition of components identifying the root causes of problems to arrive at an optimal solution.

CPI field service engineers are highly experienced technical experts capable of fully servicing many compressor makes and models, either individually, as a maintenance team working on-site with an operator’s own personnel or supervising third party service personnel.

Our reputation on customer sites is highly regarded and our expertise is utilized on the most critical of installations. Through our component and full compressor knowledge, we bring the optimum level of total compressor support.

With more than 25 years of proven performance, the original Fivealloy coating and plasma spray process, supplied exclusively through CPI, part of the Howden group, is an ideal method for repairing compressor piston rods, cylinders and cylinder liners.

CPI's extensive range of reciprocating compressor products and services.

Atmospheric rupture assemblies are used to signal excessive pressure in a system.

Balancing Valves (BV) increase the efficiency and reliability of all divider block systems operating at high pressures by balancing the effect of injection point differentials on the divider block.

CPI check valves are designed for high pressure applications where reverse flow and leakage must be kept to a minimum.

Check Valve Protector and Extreme Duty Check Valve

All the accessories necessary to get the most out of our divider blocks and to keep your compressor and lubrication system running at peak efficiency.

Annual PM guide for divider block lubrication systems.

Annual PM guide for divider block lubrication systems.

Methanol injection pumps are often used in wellhead and pipeline applications.

CPI’s HP+ divider blocks are a high performance product line.

The HVLP (High Volume Lubricator Pump) is designed to deliver precise quantities of lubrication oil to engines, compressors and other industrial applications.

The lube guard pump assembly provides protection for the lubrication system by verifying that the camshaft is rotating while also indicating a low oil level condition in the lubrication box.

The oil and lubrication system plays a very significant role in the performance of a reciprocating compressor.

The oil and lubrication system plays a very significant role in the performance of a reciprocating compressor.

CPI’s precise manifold bars are used to create a more efficient lubrication system.

The CPI Model P55 pump is an updated version of the Premier Model P55 designed to retrofit Premier, Mega, McCord and Lincoln* lubricator boxes.

The Neomag® cycle indicator follows the divider block piston movement so the operator can monitor and control oil consumption, set lube rates, and easily spot problems in the divider block system.

The CPI POPR® pop open pressure relief valve is designed to replace atmospheric rupture assemblies, being automatically activated when the divider block system over pressures.

Proflo® Cycle Switch is a single pole, single throw magnetically operated reed switch.

The CPI purge gun provides a convenient, cost effective method to remove air from the divider block system to ensure all lubrication points will receive lubrication immediately on start-up of the compressor.

Standalone lubrication system console designed specifically for hazardous environments and a wide range of industrial machinery, including reciprocating compressors and reciprocating pumps. Cost-effective solution tailored for smaller and less critical compressors

SAFEGUARD™ lubrication system console has been engineered as standalone lubrication console for hazardous locations and all types of industrial machinery including reciprocating compressors and reciprocating pumps. Configurable allowing for multiple options so that you never need to shut down your compressor for scheduled lubrication system maintenance.

The Proflo® Jr. monitoring device provides shutdown protection for your compressor based on the operation of the cycle times of the divider block system.

The Proflo® PF1 monitoring device provides shutdown protection for your compressor and collects operation data by monitoring the cycle times of the divider block system.

The Proflo PF2 is a programmable shutdown device used to monitor the lubricant flow of divider valve metering systems.

CPI offers the DropsA® SMX product line as an affordable performance product.

CPI’s XD+ divider blocks are an extreme duty performance product line.

Correct installation of packing rings is essential to prevent damage or loss of compressor efficiency.

The CPI EMISSIONGUARD™ ES³ expandable static seal is the first seal designed for optimum sealing when your compressor is not running and remains pressurized.

CPI EMISSIONGUARD™ purge panels control and monitor the supply of an inert gas, such as nitrogen, into the packing assembly(s) of a reciprocating compressor.

CPI's low emission packing ring that multiplies the benefits of a tangent to rod ring and a step tangent ring by combining the two rings into one, providing a more efficient seal, reduced friction and extended lifetime.

The word packing comes from the method of sealing in pressure where the stuffing box around a pump or compressor shaft is “packed” with a soft material. The type of seal we will discuss is a mechanical seal.

CPI designs and manufactures a complete line of high-performance packing and wiper rings, along with piston and rider rings, to meet a wide range of reciprocating compressor applications and demands.

To provide positive control of lubrication, oil wiper rings are essential in preventing oils from causing contamination of gases and leading to failure of other critical parts within a compressor.

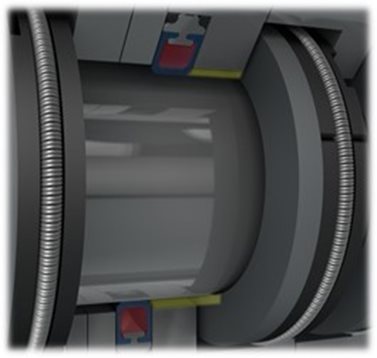

The packing case is critical to the efficient operation of the piston rod packing and the sealing of the cylinder.

CPI’s roller-type wear detector will trigger a notification to operators indicating piston rod drop, ensuring an adequate time frame and opportunity for convenient shut-down before critical damage can take place.

CPI materials for pump wear parts are available in a large range of bushings sizes, are easy to machine and install with the proper interference fit.

Showcasing our expertise to offer cylinder upgrades of all makes & models of reciprocating compressors.

CPI, designs and manufactures a wide range of high quality sealing and wear components, custom sized according to the needs of the compressor.

Even the smallest components can interrupt uptime and alter productivity. As an experienced and reliable partner, CPI is ready to respond with a solution at a moment’s notice, anywhere in the world.

CPI’s Baton Rouge service center has experts who can provide certified maintenance and reconditioning to keep your machines performing at peak efficiency.

CPI, part of the Howden group, is a leading manufacturer of precision engineered components for reciprocating compressors used in petrochemical, refining, natural gas, and offshore industries in Eastern Canada.

CPI, part of the Howden group, is a leading manufacturer of precision engineered components for reciprocating compressors used in petrochemical, refining, natural gas, and offshore industries.

Even the smallest components can interrupt uptime and alter productivity. As an experienced and reliable partner, CPI is ready to respond with a solution at a moment’s notice, anywhere in the world.

Solutions for Common High-Speed Compressor Issues.

CPI, part of the Howden group, is a leading manufacturer of precision engineered components for reciprocating compressors used in petrochemical, refining, natural gas, and offshore industries in Nigeria.

CPI, part of the Howden group, is a leading manufacturer of precision engineered components for reciprocating compressors used in petrochemical, refining, natural gas, and offshore industries in Western Canada.

CPI can design and manufacture a wide range of valve styles to suit your compressor.

High lift valves with low pressure drop across the sealing elements best suited for low differential pressures and slower speed compressors.

CPI Unloader Diaphragm Actuators are used for replacing old style leaking or worn out unloader actuators.

In the compressor industry, even the smallest components can interrupt uptime and productivity. In order to achieve continuous operation, you need an experienced and reliable partner.

CPI Hi-Flo™ RD valves feature aerodynamic radiused profiled rings that control and seal process gas as it flows in and out of the compressor cylinder.

CPI's Hi-Flo™ RS (Replaceable Seat) valves eliminate the need for off-site reconditioning.

CPI Hi-Flo™ VP valves feature aerodynamic V-profiled rings that control and seal gas as it flows in and out of the compressor cylinder.

The Indicator Ported Valve (IPV) is designed to allow performance analysis and routine diagnostic testing of compressor cylinders that do not have drilled and tapped indicator ports.

Comprehensive range of metallic and non-metallic Ported Plate Valve assemblies and components.

Redesigned compressor cylinder and valves to eliminate cracking at fertilizer manufacturer.

Piston and Rider Runtime Improvement in Crude Nitrogen Compressor

CPI 138 Lead-Free Material in Oxygen Compressor Service

CPI 184 Material Ring Success in Low Temperature BOG Compressors.

CPI 192 Material Presssure Breaker Eliminates Blow-by Issues.

Hydrogen compressor conversion to non-lubricated in food processing

Special Polymer Alloy for high duty gas compressor piston and rod seals

TR² success on the 2nd stage of an ethylene primary compressor

High Pressure Non-Lube Hydrogen TR² Packing Ring upgrade

CPI EMISSIONGUARD TR2 Critical Non-Lube High Wear Rate Application.

Eliminating Cooling from Packing Cases by Upgrading to CPI Polymer Alloy Packing Ring Materials.

Hi-Flo RS Valves - Easily Replaceable in the most remote locations.

Hi-Flo valves increase valve life from 6 weeks to 40 months.

Piston Redesign Extends Life of Cylinder Bores

Vertical pump problem solved by applying CPI's PUMPGUARD material.

Installing SAFEGUARD Lubrication System to optimize lubrication rates

High pressure bone-dry hydrogen compressor upgraded to Special Polymer Alloy materials

Redesigned Valve Cage & Cover Eliminate Multiple Gas Leaks

Cryogenic valves - metallic to non-metallic plate conversion

Service story - cylinder valve seat repair.

EMISSIONGUARD TR² Product Brief

Pneumatic Rolled Diaphragm Actuators Product Brief

Finding the Optimal Lubrication Rate for Your Compressor

Describes various ways in which the Piston Ring can be cut to allow the ring to make constant sealing contact on the cylinder bore, maintain sealing along the stroke, provide end clearance, ease of installation over the piston and into the grooves.

CPI Plug Style Unloader Actuator Upgrades Product Brief.

HVLP Pumps

P55 Lubricator Models – 704800, 732201, GE824300

P55 Lubricators Part Numbers: 65001000704003E

P55 Lubricators Part Numbers: 65001000704103E

P55 Lubricators Part Numbers: 65001000704205E

P55 Lubricators Part Numbers: 65001000704305E

P55 Lubricators Part Numbers: 65001000711003E

P55 Lubricators Part Numbers: 65001000816705E

P55 Lubricators Part Numbers: 65001000711100E

P55 Lubricators Part Numbers: 65001000711103E

P55 Lubricators Part Numbers: 65001000711305E

P55 Lubricators Part Numbers: 65001000711300E

P55 Lubricators Part Numbers: 65001000711000E

P55 Lubricators Part Numbers: 65001000711200E

P55 Lubricators Part Numbers: 65001000711205E

Proflo® PFCS Part Number: 65004000000PFCS

Sustainable Management Group (SMG) certificate of registration.

Divider blocks are single line progressive hydraulic systems used to divide a single lubrication feed to multiple points while allowing each point to receive a different quantity of oil

The High Volume Lube Pump (HVLP) delivers accurately measured quantities of lubricating oil to the divider block lubrication system for distribution to rod packing, compressor cylinders, power cylinders and various lubrication points on engines and compressors

The CPI Model P55 Pump series features heavy duty metering, precision, and self lubricating pumps capable of pumping small amounts of mineral or synthetic oil to machinery injection points at pressures up to 7500 psi

CPI lubrication systems deliver the perfect amount of oil, under pressure and at regular intervals, to moving parts on all types of industrial machinery

The Proflo PF2 is a programmable device used to monitor the lubricant flow of divider block metering systems

The captured proximity switch, a single pole single throw magnetically operated reed switch, sends a dry contact signal to any PLC-style control panel or directly to the lubrication monitor, such as the Proflo® PF2 monitoring device.

CPI 111 is a self-lubricating material which has been specially developed for use in high duty, oil free atmospheric air compressors, such as those used in the manufacture of PET bottles.

CPI 114 is a proprietary filled PTFE compound which has been developed especially for dry oxygen compressors.

CPI 138 has been developed especially to give safe and reliable use in dry oxygen compressors and has undergone ignition-testing for this demanding application. CPI 138 is also suitable for dry gases which contain oxygen as a constituent, such as bone-dry air and crude argon.

CPI 184 is a proprietary polymer alloy developed exclusively by CPI, which has become the preferred material for use on non-lubricated gas compressors and in particular those gases which are ‘bone-dry’.

CPI 188 is a specially developed polymer alloy for use in oil-free dry nitrogen compressors, or in other inert gases such as helium or argon.

CPI 190 was created to meet the requirements of specific, demanding, non-lube applications.

CPI 192 is a proprietary polymer alloy developed exclusively by CPI, which has become widely specified for extreme service in both lubricated and oil-free gas compressors.

CPI 193 is a proprietary polymer alloy developed to extend the useful upper working limits of piston and rod seals in both lubricated and oil-free gas compressors.

CPI 196 special polymer alloy has been developed to meet the requirements of non-lubricated dry nitrogen compressors, and in particular those operating at medium to high pressures.

CPI 197 proprietary polymer alloy has been developed to meet the requirements of non-lubricated dry nitrogen compressors, and in particular those operating at very high pressures.

CPI 303 has been developed especially to give safe and reliable use in dry oxygen compressors and is ignition-tested and approved for this demanding application.

CPI 307 is a special self-lubricating material, which can be used to provide reliable operating lives in non-lubricated, atmospheric air compressors.

CPI 315 is a non-fibrous material, non-abrasive and provides a combination of good mechanical properties and wear resistance, equally suited to both lubricated and non-lubricated compressor applications.

CPI 321 is a proprietary blend of special fillers and virgin PTFE. It has been developed for use in oxidising gases and those sensitive to MoS2.

CPI 543 is a proprietary reinforced thermo-plastic material developed for use in CPI compressor valves CPI 543 is the most widely selected valve disc material for use in a broad range of operating conditions.

CPI 560 is a proprietary high performance material developed exclusively by CPI. It is suitable for use in both lubricated and oil free applications, where its resistance to extrusion is advantageous.

CPI 565 is a proprietary reinforced thermoplastic material developed for use in CPI Compressor valves. This CPI material exhibits very low moisture absorption and is therefore particularly beneficial in saturated gas applications such as atmospheric air or saturated carbon dioxide. CPI 565 also offers an exceptionally high temperature resistance.

CPI 566 is a proprietary reinforced thermo-plastic material developed for use in CPI compressor valves CPI 566 exhibits very low moisture absorption and is therefore particularly beneficial in saturated gas applications such as atmospheric air or saturated carbon dioxide.

CPI 568 is a high strength polymer used for valve components requiring high strength, at the same time offering good resistance to high temperatures and chemical resistance to a wide range of gases and liquids.

CPI PUMPGUARD™ 182 material is a proprietary polymer alloy for pump bushings designed to be used for wear rings, guide bushings and thrust washers.

Edited February 2022 - Effective May 1, 2016 CPI, part of the Howden group, released the HP+ and XD+ Divider Block product lines. These products serve as direct replacements for the previous HP and XD Divider Blocks.

Improvements have been made to the internal workings of the Model P55 pumps adding to their longevity and efficiency.

An internal check valve with 10 PSI cracking pressure is being implemented into all P55 pump models by the end of 2017.

Ratchet lubricators will be transitioning from the old design which used an internally mounted ratcheting gear assembly.

Technical Bulletin regarding the use of CPI’s P55 vacuum pumps (model numbers 6501800P55V301S, V401S, V601S) with applicable Lincoln lubricator boxes

United States, Stafford, TX +1 (281) 207-4600

CPI BATON ROUGE

11997 Airline Hwy

Baton Rouge, LA

70817

Phone: (225) 752-4272

CPI LOS ANGELES

19520 Rancho Way, Suite 206

Rancho Dominguez, CA

90220

Phone: (310) 223-1101

CPI STAFFORD (HOUSTON)

4410 Greenbriar Drive

Stafford, TX 77477

Phone: (281) 207-4600

CPI PHILADELPHIA

107 William Leigh Drive

Tullytown, PA 19007

Phone: (215) 946-0845

CPI BRANTFORD

124 Shaver Street

Brantford, Ontario, Canada

N3T 5M1

Phone: (519) 753-8671

CPI EDMONTON

6308 Davies Rd NW

Edmonton, Alberta, Canada

T6E 4M9

Phone: (780) 468-5145

CPI CHINA

28-3 Rongle East Roads

Shanghai, China 201612

Phone: +86 (0) 21 67871990

CPI SOUTH KOREA

42-16, Hwachang 1-gil

Cheongnyang-eup, Ulju-gun,

Ulsan, Republic of Korea, 44986

Phone: +82 522686900

CPI FRANCE

95 Rue de Neuf-Mesnil,

Bâtiment A8

Feignies, France 59750

Phone: +33 (0) 327 63 16 64

CPI SPAIN

Calle de los Aragoneses, 2

Alcobendas, Madrid, Spain

28018

Phone: +34 (0) 91 651 93 55

CPI GERMANY

Robert-Bosch-Straße 3

D-64572 Büttelborn

Phone: +49 6152 9316-0

CPI UK

Unit 5 Smitham Bridge Road

Hungerford, RG17 0QP

Phone: +44 (0)1488 684 585

CPI NETHERLANDS

Harregatplein 17

Zuidland, Netherlands 3214

VP Zuidland

Phone: +31 (0) 1816 63149